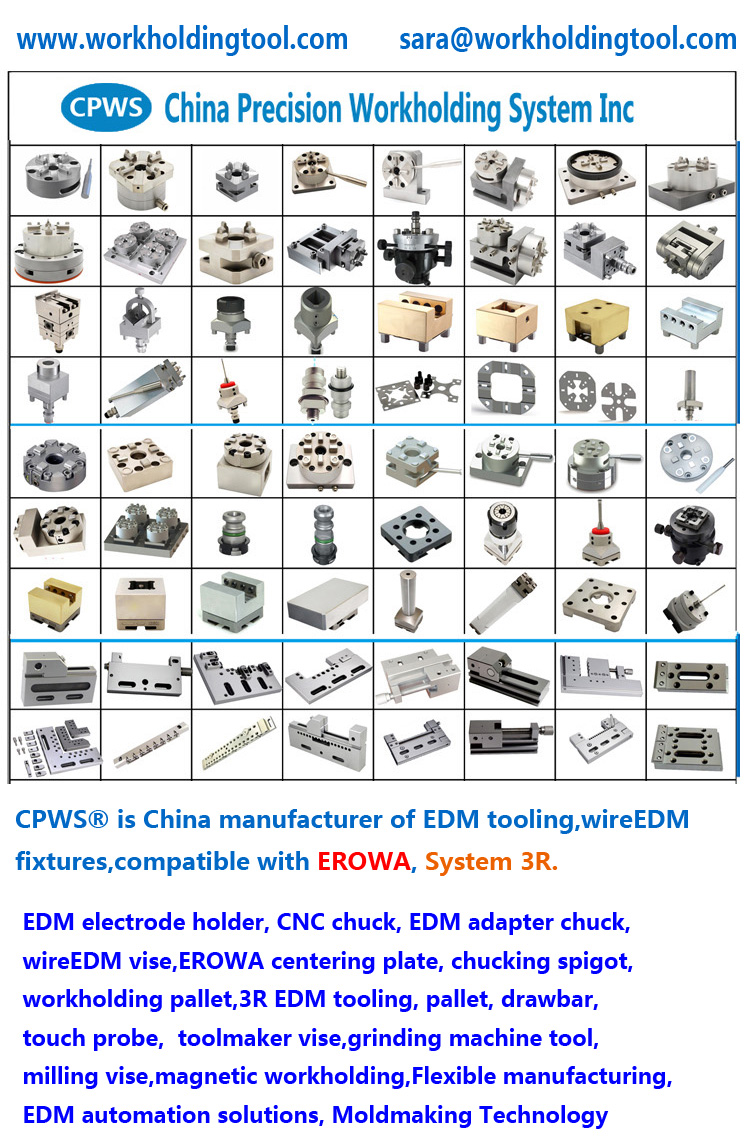

MacroStandard & MacroHighPerformance

… reduces setting-up times.

… ensures precision and quality.

… has automatic air-blast cleaning of the references in the pneumatic chucks.

… has higher locking force in the pneumatic chucks – turbo locking.

… has references of cemented carbide or hardened ground steel.

… is suitable for automatic changing with System 3R’s automation program.

If you want to compete in the global manufacturing industry, you need to study every aspect of efficiency. It’s a matter of extracting the highest possible number of spindle-hours from each machine, every day of the week. And here, the importance of a high-class reference system can never be over-estimated. A reference system which reduces setup times to a few minutes.

Macro is such a reference system. A system that minimises the throughput time, and which, thanks to its accuracy, practically eliminates rejects. A system that increases flexibility and profitability. A system that increases competitiveness and ensures the success of its users.

Among users world wide, the Macro system is a byword for precision. And with good reason, since very single Macro product is thoroughly checked before it is dispatched. But precision can be graded too. The Macro products are therefore “classified” in terms of accuracy, material and life – but always with full compatibility – as Standard, High Performance and Nano. Even so, it’s worth remembering that the accuracy of a system is determined by the product with the lowest classification.

- Repetition accuracy:

MacroNano – within 0.001 mm

MacroHighPerformance – within 0.0015 mm

MacroStandard – within 0.002 mm - Locking force – 6000 N

- Fixed index positions 4×90°

- Required air pressure, pneumatic chuck – 6±1 bar

- Recommended max workpiece weight – 50 kg.

- Recommended tightening torque, manual chuck – 6 Nm

- Recommended max workpiece weight – 50 kg.

Metric US Measurements

Spindle chucks

Current Page:

1/8

First Page Pre Page 1

2

3

4

5

6

7

8

Next

Last Page

- Pre:CPWS from China–supplier of equivalent system3R tooling Ref 2018/4/25

- Next:Yahoo! Or sale of assets in Asia to promote Alibaba group IP 2012/5/23

The post CPWS from China-manufacturer-Compatible 3R EDM spindle chuck table chuck pallet holder vise appeared first on CPWS®-China Precision Workholding System Inc.

没有评论:

发表评论